UPS Battery Maintenance & Testing Services

Uninterruptible Power Supply (UPS) Systems and Batteries

Prevent costly downtime with a tailored turnkey UPS battery and equipment solution. Partner with our trusted UPS battery specialists to implement UPS service and maintenance plans, battery and component replacement services, and robust remote monitoring to help avoid future UPS failures and maintain business continuity.

Ensure The Reliable Operation of Your Battery Backup

ANS performs UPS battery installation, factory-recommended preventative maintenance, testing, and monitoring to ensure uninterruptible power supply systems are operating at peak performance.

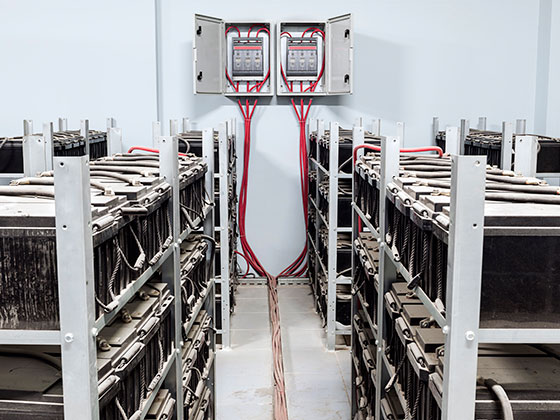

UPS Battery Installation

Delegate complex uninterruptible power supply system and battery installation to our team of UPS specialists who are trained to meet rigorous quality standards and adhere to manufacturer specification guidelines.

- Maximize facility up-time

- Maintain environmental compliance

- Avoid liability with single-source accountability

- Seamless integration of new/replacement batteries

- Delegate EF&I services

UPS Battery Testing

Proactively identify and prevent costly UPS failures with regularly scheduled UPS battery testing. ANS provides periodic battery testing to maximize the life cycle of the system, maintain manufacturer warranty claims, and ensure the reliability of your UPS equipment.

- Annual inspection and testing

- Ensure regulatory compliance

- Identification of weak cells and faulty connections

- Reduce battery replacement rate and frequency

- Impedance and load bank testing

Monitoring & Maintenance

Our customizable UPS battery and equipment preventative maintenance programs provide facilities actionable and essential diagnostics to help extend battery life and maintain facility up-time, saving businesses money by avoiding unnecessary battery replacements.

- 24/7/365 emergency service

- Predictive maintenance

- Guaranteed response times

- Remote UPS monitoring software

- Proactive replacement of UPS components

Why ANS?

A one-stop-shop for all your critical power needs, ANS delivers reliable UPS battery solutions to meet the demands of technical and demanding environments. UPS battery technicians undergo continuous training to meet rigorous quality standards. All UPS battery services adhere to manufacturer specifications and specific regulatory standards such as NEC, ANSI, NFPA, IEEE, and OSHA.

- 24/7 responsive support

- Rapid trouble ticket resolution

- Deep DC & AC power expertise

- State-of-the-art battery testing equipment

- Authorized distributor of Deka batteries

- Licensed electrical contractor across multiple states

- Services all types of UPS batteries (VRLA, Wet Cell, NiCd, & Lithium-ion)